Machinery

Your project is in expert hands. At our machines, skilled technicians turn every piece of metal into a true showpiece. Curious which machines make that possible?

All dimensions are in millimetres.

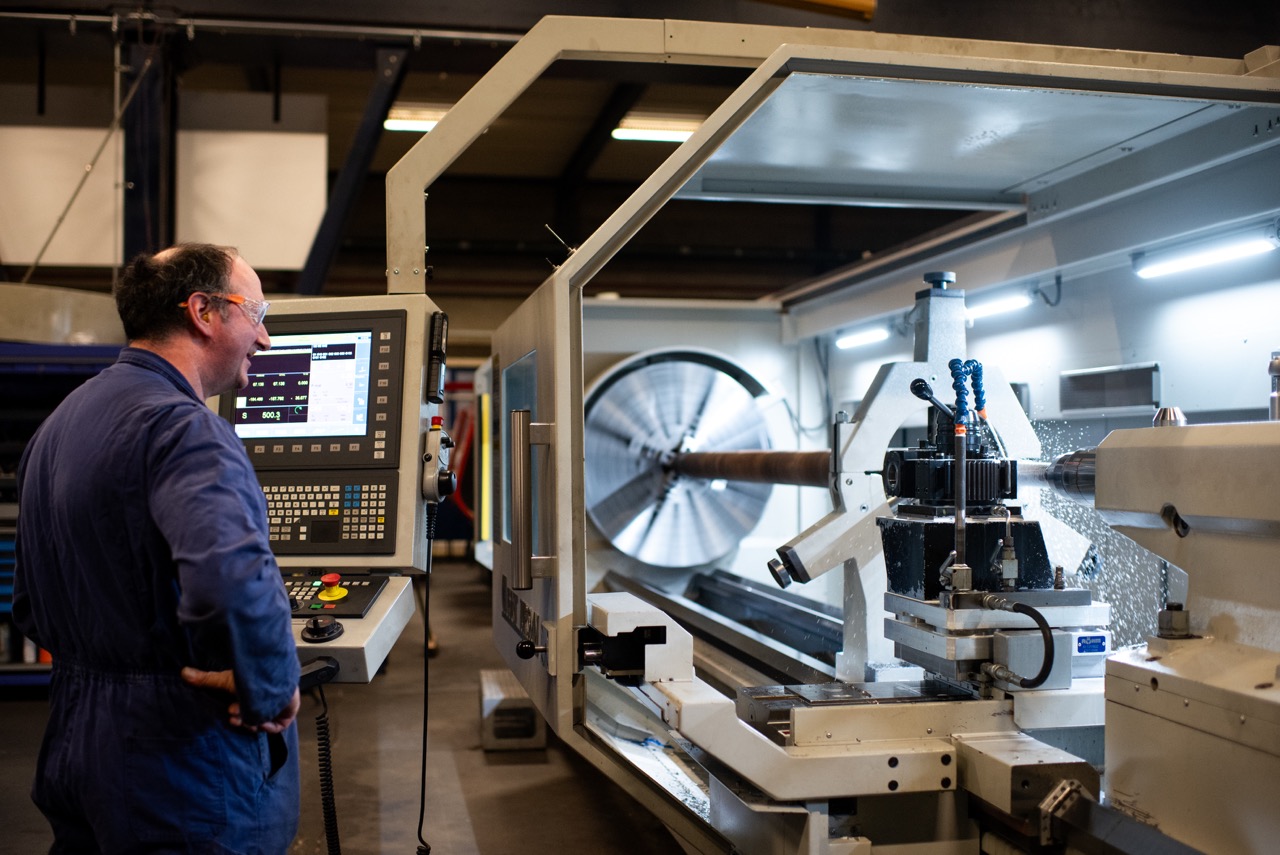

Turning operations

We operate various types of lathes, primarily CNC-controlled lathes. These machines offer a high level of precision, ensuring consistent quality and dimensional accuracy, even for small to medium-sized production runs.

Lathes (CNC)

Capacity: up to Ø500 – L 2,000

Our machines

- Mazak Integrex 35

- Mazak Quick Turn 350MY

- Mazak NEXUS QTN350-II MY

- Mazak QSM 250M x 1000 < li>TOS MASTURN 50/1500

- Weiler E60 x 2000

- Weiler E50 HD/SL2

- Weiler E50/2000

- Weiler E35/D1/950

Large lathes (CNC)

Capacity:up to Ø2,200 – L 6,000

Our machines

FAT TUR 1100 MN x 6000

SCHIESS FRORIEP 20DS180

COMEV TITANO 65 - 3000

EMCO PADOVANI 360

Milling machines

Our advanced milling machines can accurately process workpieces up to 10 by 3.5 meters in a single setup. Thanks to our flexible milling heads, each setup is optimally utilised, resulting in efficient and precise machining of your components. This enables us to confidently deliver even large and complex projects, without compromising on dimensional accuracy or surface finish.

CNC Milling

Capacity: up to 3000 x 800 and max 5 tons

Our machines

- DECKEL-MAHO DMC63V

- Mori Seiki NVX-7000/50

- Mori Seiki NVX-5100II/40_M

- DOOSAN Mynx 5400/40

Milling/boring large pieces

Capacity: up to 10,000 x 3,500 x 1,500 and max 25 tons

Our machines

- Correa Norma 45

- MATEC 30 HV

- TOS FSS 80 CNC

- TOS WHQ 13 CNC

- ZAYER 30 KCU 10000

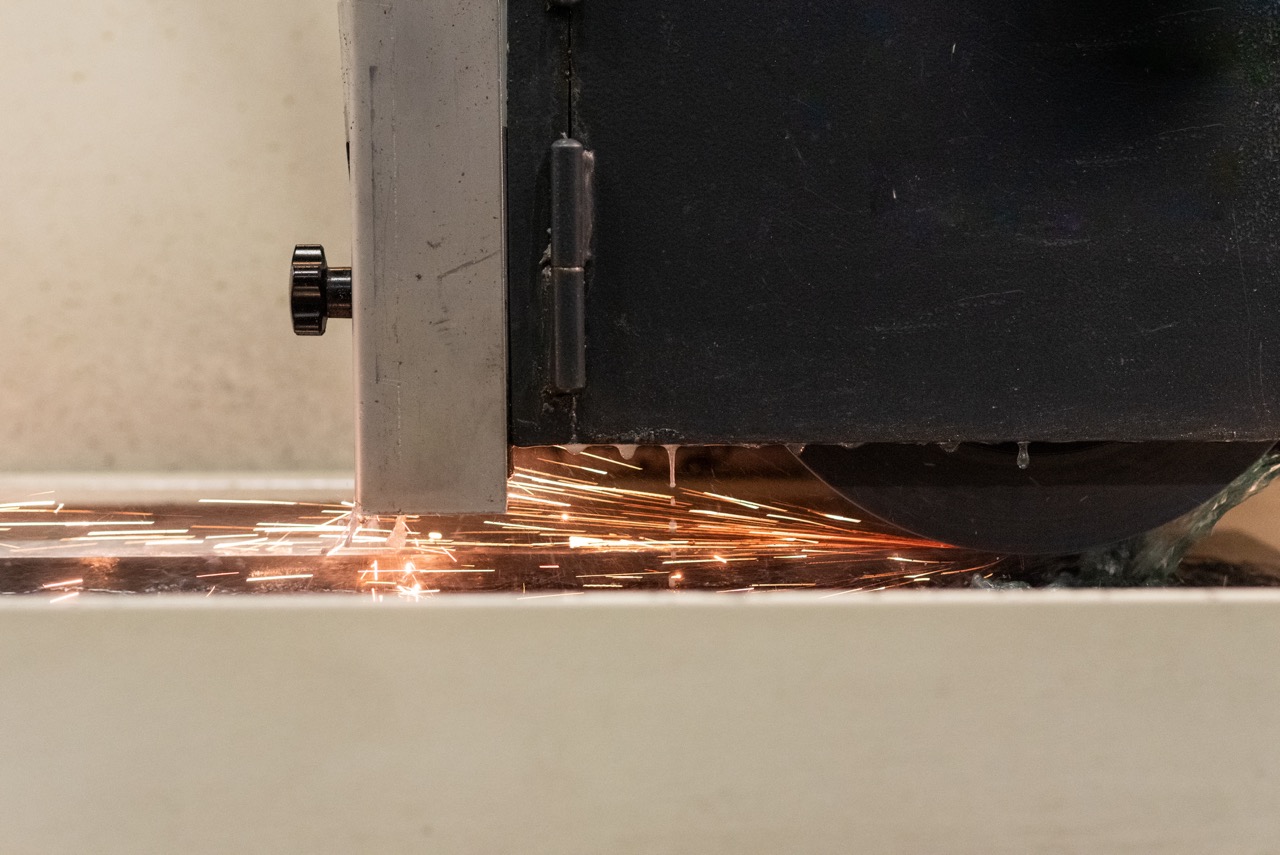

Our welding department

At MKB, we have a spacious welding department equipped with multiple professional welding stations and worktables. Our expertise in various welding techniques, including MIG/MAG and TIG welding, enables us to produce both large-scale constructions and intricate, high-precision parts. We work with ferrous and non-ferrous materials such as steel, aluminium, and stainless steel, always with a focus on accuracy and structural integrity.

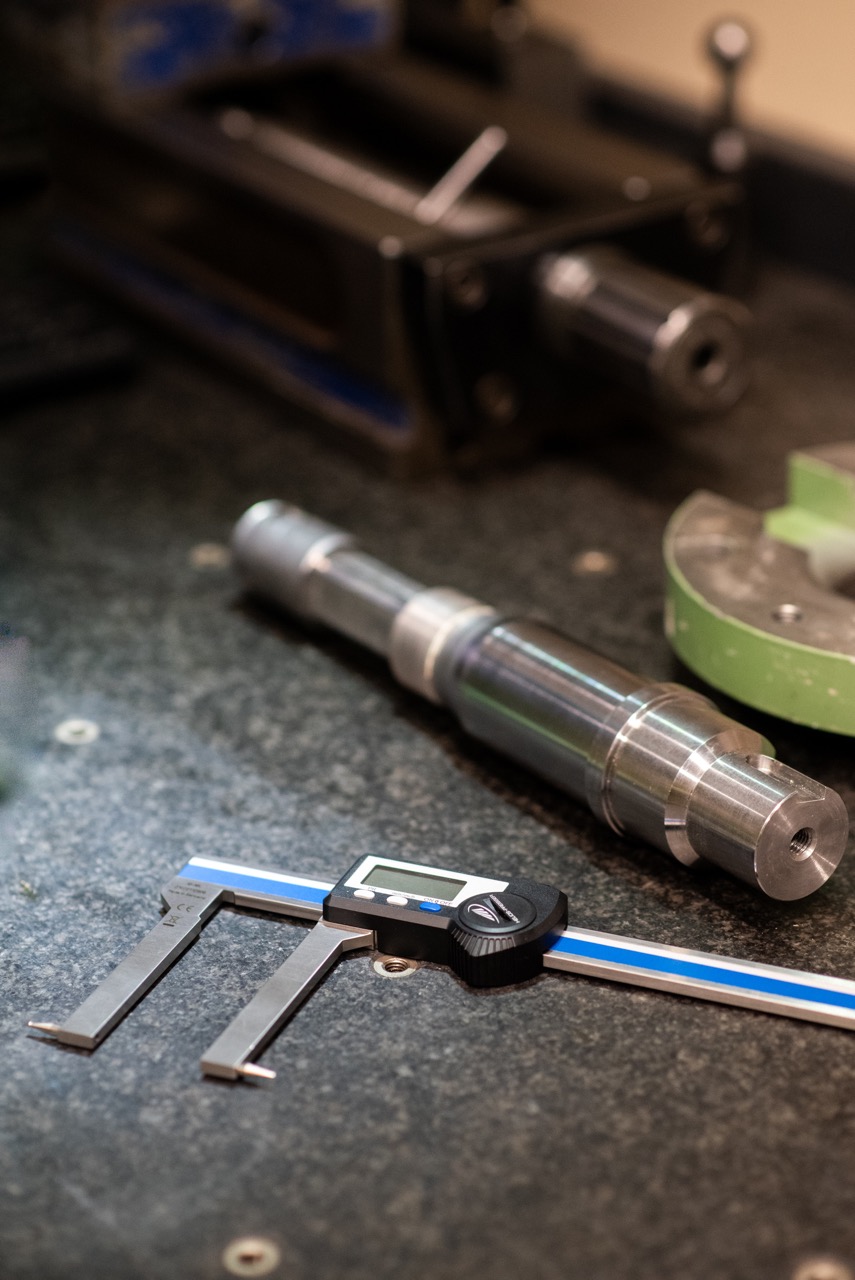

Other techniques

In our workshop, we offer a wide range of essential metalworking operations. This includes grinding and keyway broaching for highly precise components, as well as sheet metal processes such as cutting and bending. Using advanced measuring equipment, we ensure quality and tight tolerances. We also apply surface treatments like anodising and galvanising to enhance the durability and appearance of metal parts.

Sheet metal working

At MKB, we offer a wide range of sheet metal processing techniques, from cutting and bending to flame cutting and rolling, always with a focus on accuracy and custom work.

Our capabilities:

-

Cutting: up to 12 mm thick / 3,000 mm wide

-

Bending: up to 8 mm thick / 3,000 mm wide

-

Flame cutting: plasma up to 220 mm thick / oxy-fuel up to 200 mm thick

-

Rolling: up to 15 mm thick / 2,500 mm wide

-

Spray booth: 7,000 x 5,000 x 3,500 mm

We work with both ferrous and non-ferrous metals, delivering components that meet strict functional and structural requirements. Thanks to our skilled professionals and advanced machinery, we provide custom sheet metal work, from simple cladding to complex shaped or curved parts.

Grinding and keyway grooving

At MKB, we use various grinding techniques to fine-tune metal components with a focus on precision, flatness and surface finish. Our extensive machine park allows us to handle both standard grinding work and more specialised operations like keyway broaching.

-

Walther CD200

-

Kikinda A10U550

-

Chevalier Series FSG 1632

-

Keyway broaching machine Cabe 450

Our equipment:

Whether restoring contact surfaces, finishing parts to tight tolerances or cutting keyways with high accuracy — we ensure a dimensionally precise result for every component.

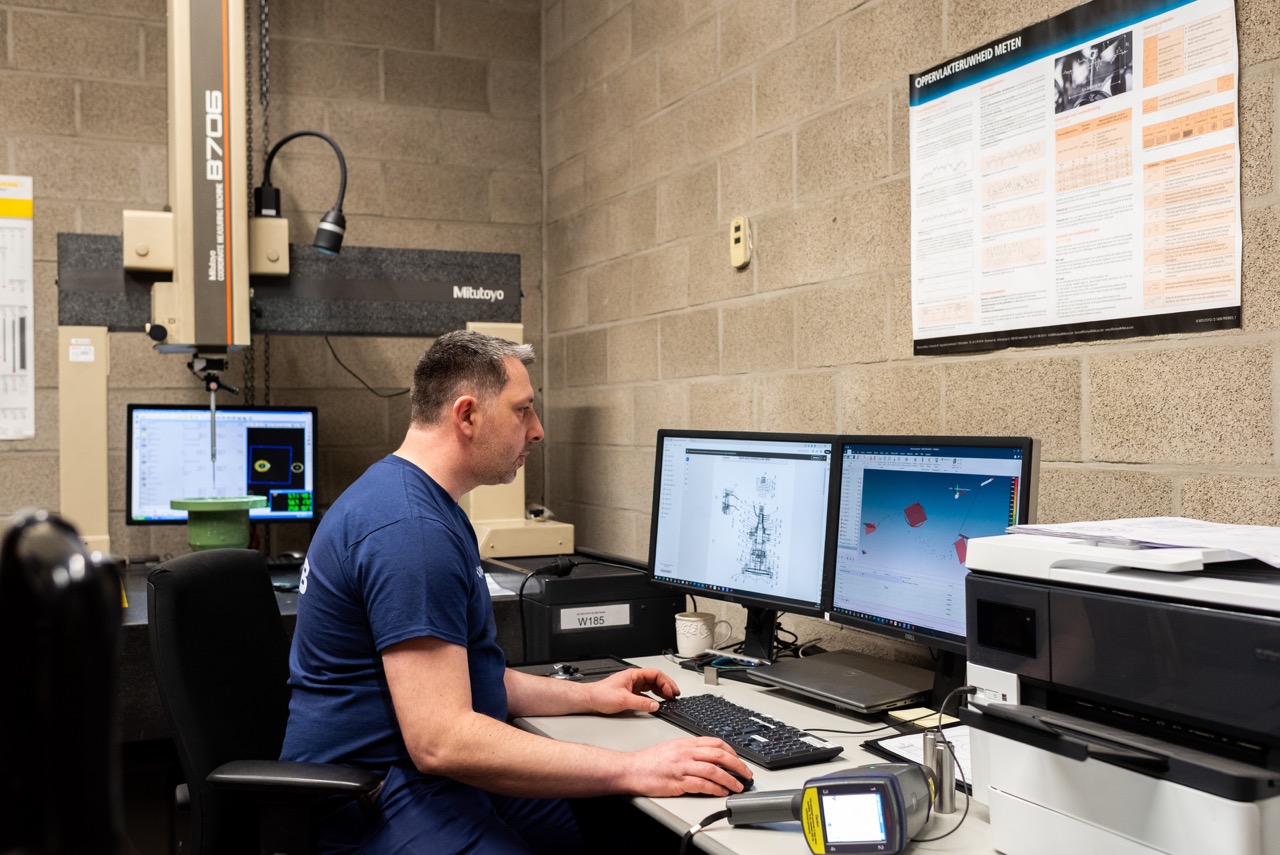

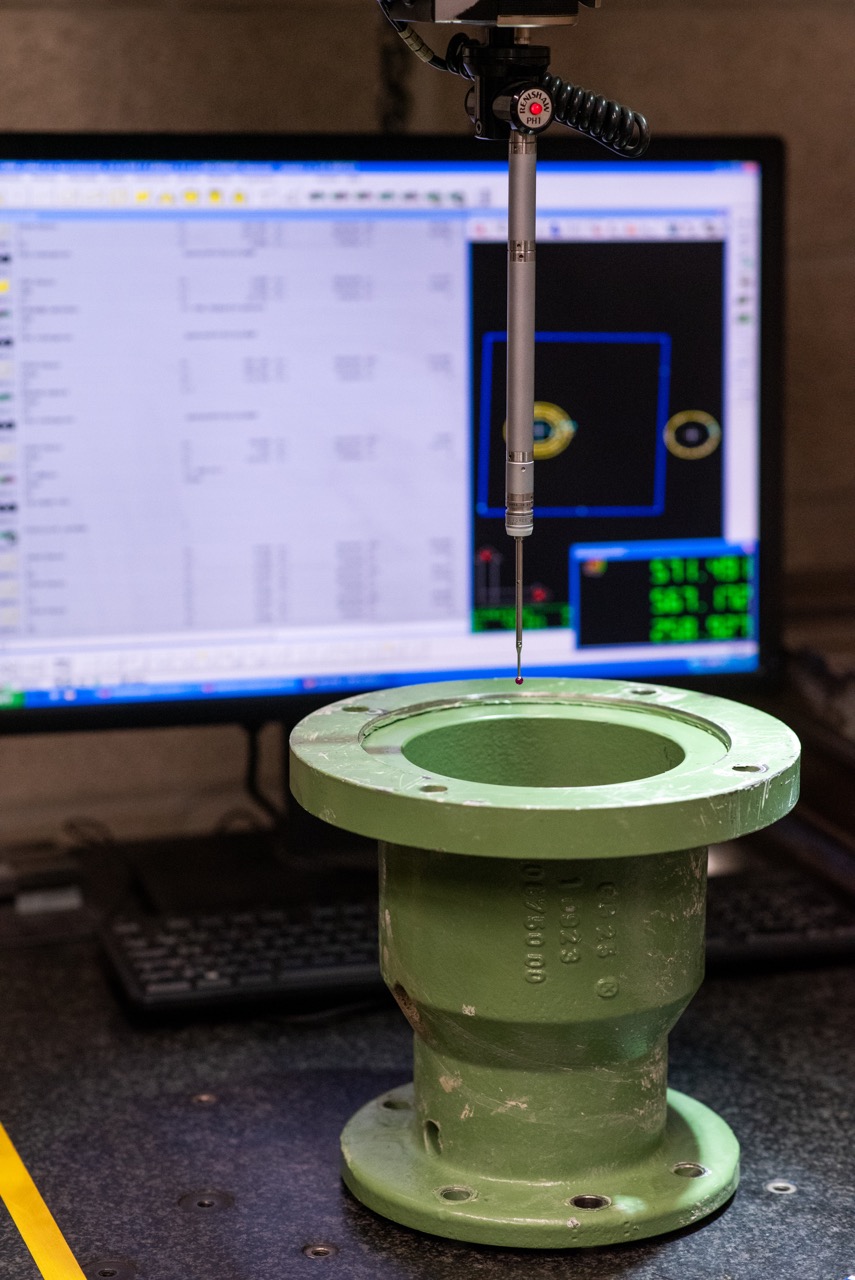

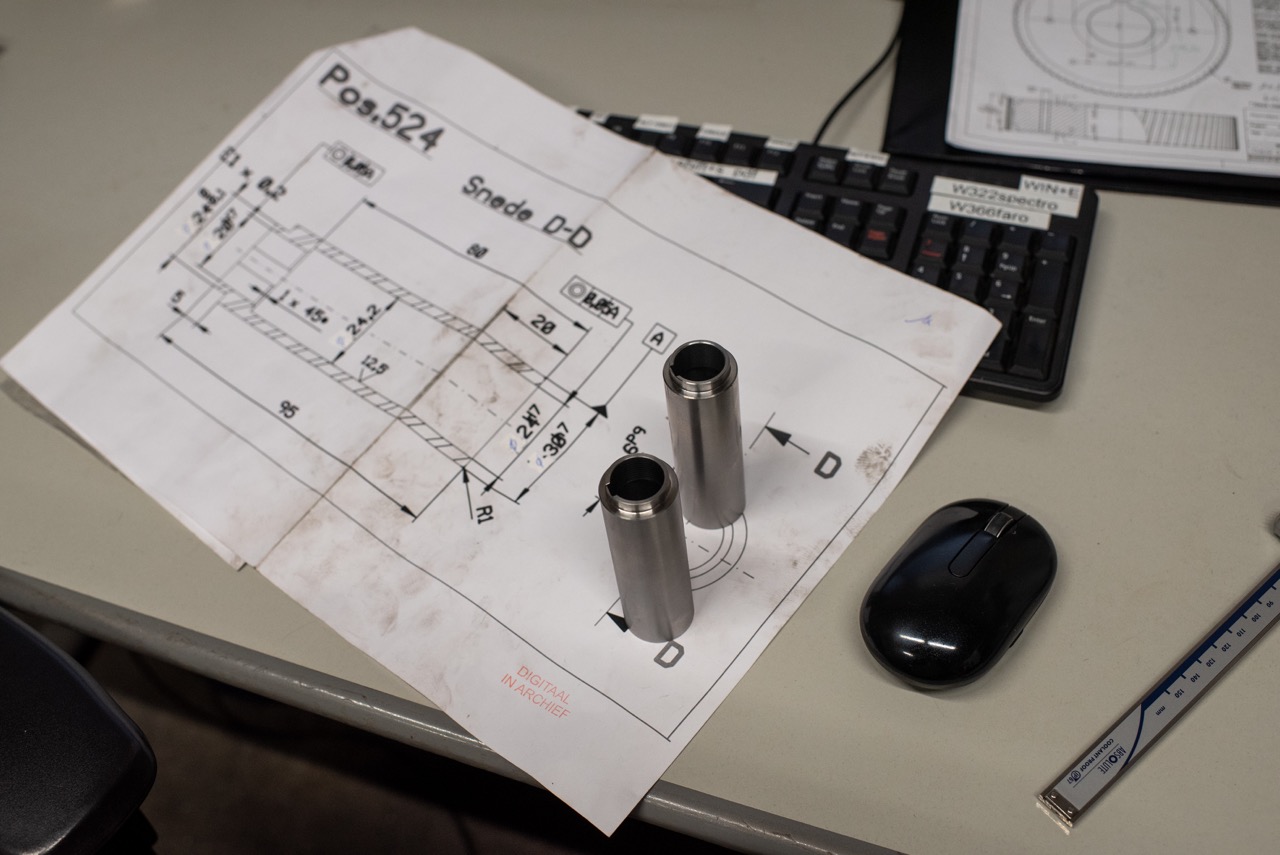

Conditioned measuring room

Measurements at your site or ours? Both are possible.

Our fully equipped metrology room features a wide range of professional instruments for precision measurement and quality control. This includes a 3D coordinate measuring machine, a mobile FARO® arm, and a handheld spectrometer for material analysis. With this setup, we perform high-accuracy inspections, both in-house and on-site.

Our measurement equipment includes:

-

Trimos Alesta 1000 (presetting device)

-

Mitutoyo coordinate measuring bench

-

FARO® Quantum S V2 measuring arm

-

Spectro xSORT Handheld X-ray (material identification)

-

WOLHPERT hardness tester

-

Time 5100 hardness tester

Engineering

At MKB, everything revolves around technical innovation and continuous improvement. Our engineering process covers the design, analysis, and development of advanced systems, structures, and components.

But we don’t stop there. Through redesign and re-engineering, we revisit existing concepts to make them more efficient, more effective, and more cost-competitive. Whether it’s developing new machinery, creating functional prototypes, or adapting existing systems to new technical requirements, we reconsider every aspect — from design and material selection to manufacturing methods and assembly.

We turn your ideas into reality — and make what’s good, even better.

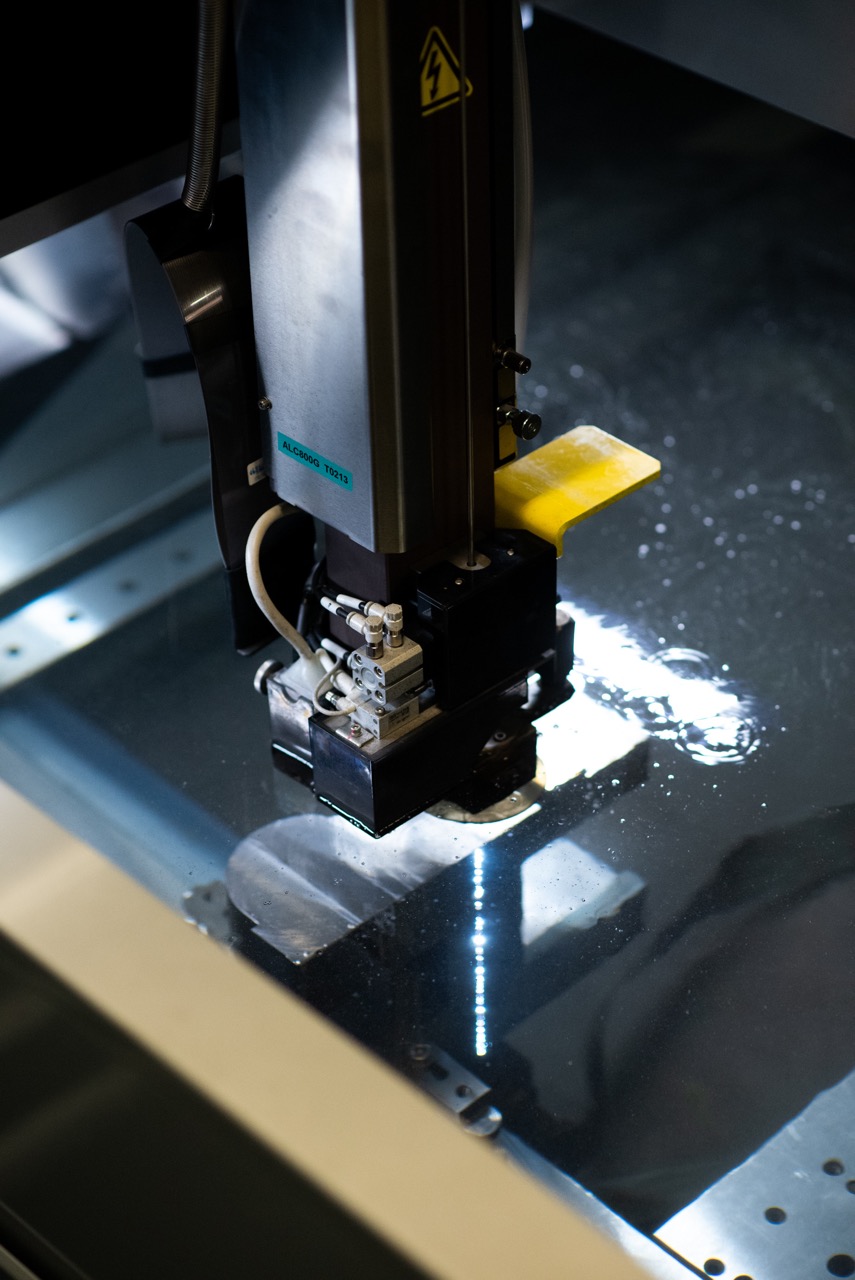

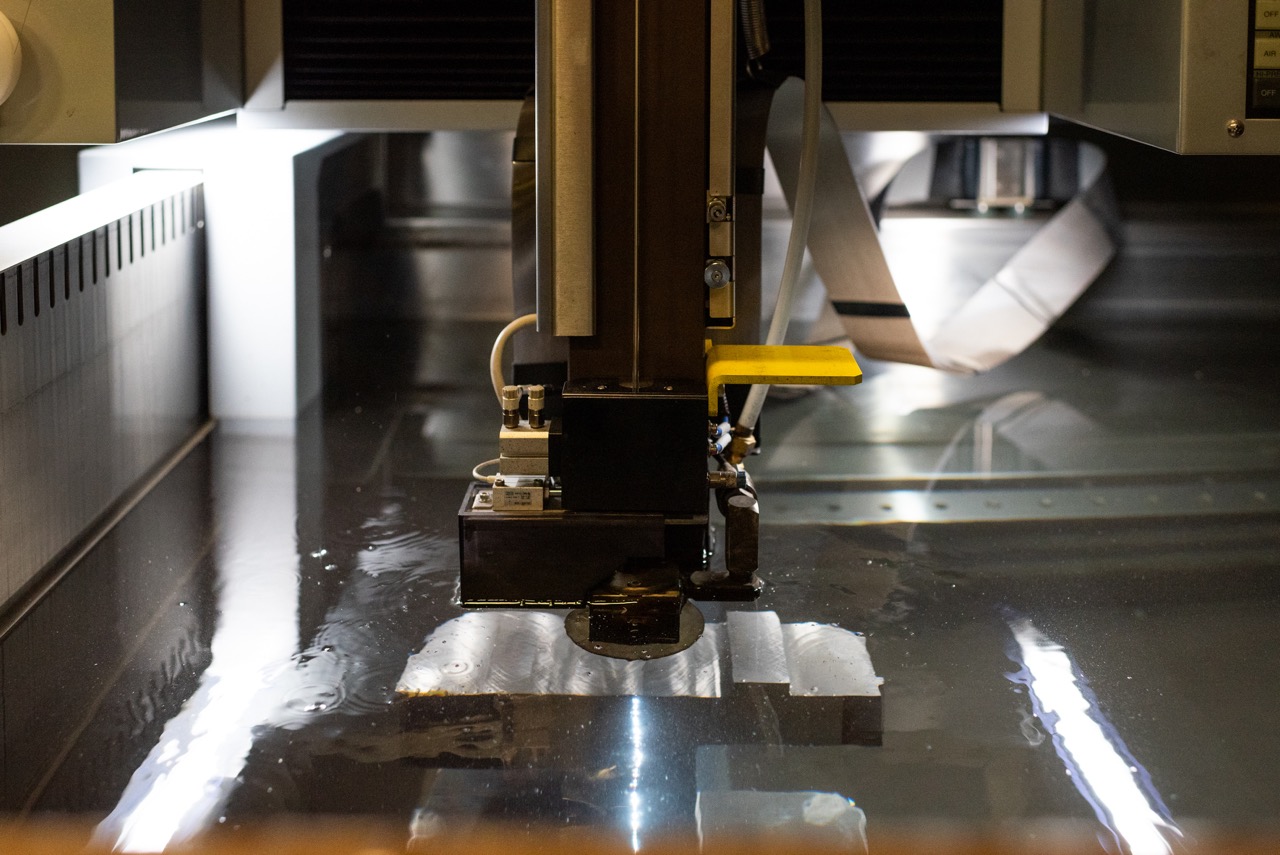

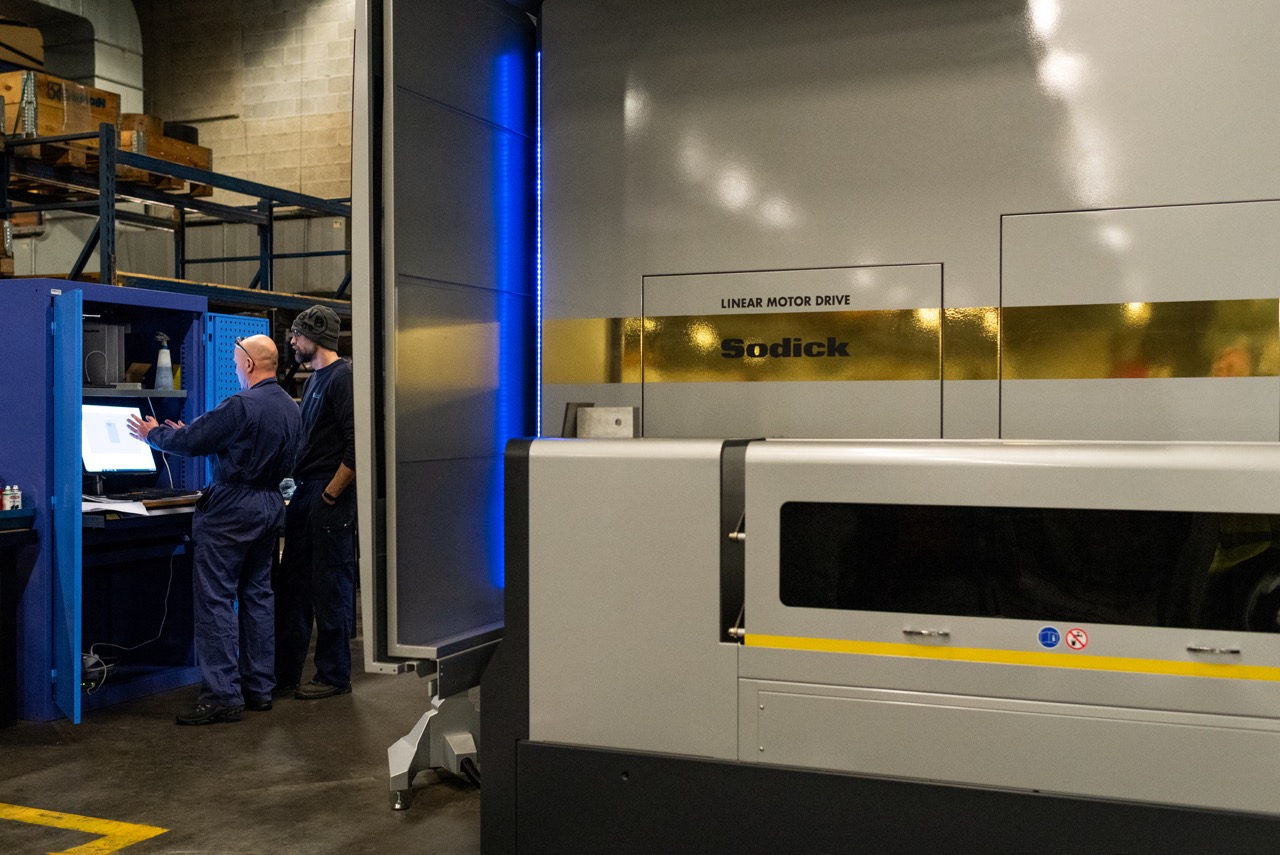

Wire spark or spark erosion

At MKB, we manufacture high-precision components that meet the highest quality standards, using our latest electrical discharge machine: the Sodick ALC 800G Premium.

EDM (Electrical Discharge Machining) is ideal for processing extremely hard materials and achieving ultra-fine detailing, even in complex geometries.

Capacity:

Workpieces up to 800 x 600 x 500 mm, with a maximum weight of 3,000 kg.

52

people

159

machines

7850 m²

workshop

98

years of experience